We run Heaven Automotive and we want to give a clear, practical guide that shows why engine service matters for fuel economy.

When airflow drops, engines often change their control strategy and MPG can fall fast. We define “dirty” as visible debris, heavy dust loading, or any sign that airflow through the element is reduced.

We explain what to expect from an engine air filter replacement service and how routine care links to real-world fuel savings.

In this guide we walk through inspection, choosing the right part, and changing the unit without letting debris into the intake.

We also preview common mistakes—poor sealing or wrong orientation—that can waste gas even after a new part is in place.

Read on to learn the shop-tested steps we use, why MERV matters, and how timely maintenance helps keep your vehicle efficient. When you’re ready, we invite you to hire Heaven Automotive to inspect and service your vehicle.

Key Takeaways

- Restricted airflow changes engine control and can lower MPG.

- Dirty means visible debris, dust loading, or reduced flow.

- Proper inspection and correct part selection prevent efficiency loss.

- Poor sealing or orientation can negate a new unit’s benefits.

- We use these same steps in our shop; schedule service if MPG drops suddenly.

Why a Dirty Air Filter Can Reduce Gas Mileage in Modern Vehicles

Restricted intake flow changes how an engine reaches its target mixture. That shift can lower fuel economy, especially when the car is working hard.

How restricted airflow changes the air-to-fuel balance and engine efficiency

When airflow is limited, sensors and control logic alter injection and timing to protect the combustion process.

These adjustments can reduce efficiency under load and cut overall performance.

Why “the engine works harder” can translate into more fuel used

A clogged element often means more throttle input for the same speed. That uses extra energy and changes shift behavior in automatic gearboxes.

- On hills or during merges, restricted flow can force richer mixtures.

- Sensors compensate only so far; heavy loading still hurts driveability.

- It’s not just dirt — it’s reduced volume of usable air and trapped particles that limit system throughput.

Signs Your Air Filter Is Clogged and Hurting Performance

We often spot intake restriction from simple driveability cues before running diagnostics.

You can often spot a clogged unit before sensors do by feeling how the car responds.

Reduced acceleration and sluggish throttle response

One of the first complaints we hear is a lazy throttle feel and slow acceleration. Drivers report needing more pedal travel to get the same passing speed. That points us to the intake as a quick checkpoint.

Rough idle, hesitation, and unexpected drops in MPG

Rough idle or hesitation during throttle transitions can indicate unstable flow. We also watch for sudden MPG loss when nothing else changed—same route, tires, and driving style.

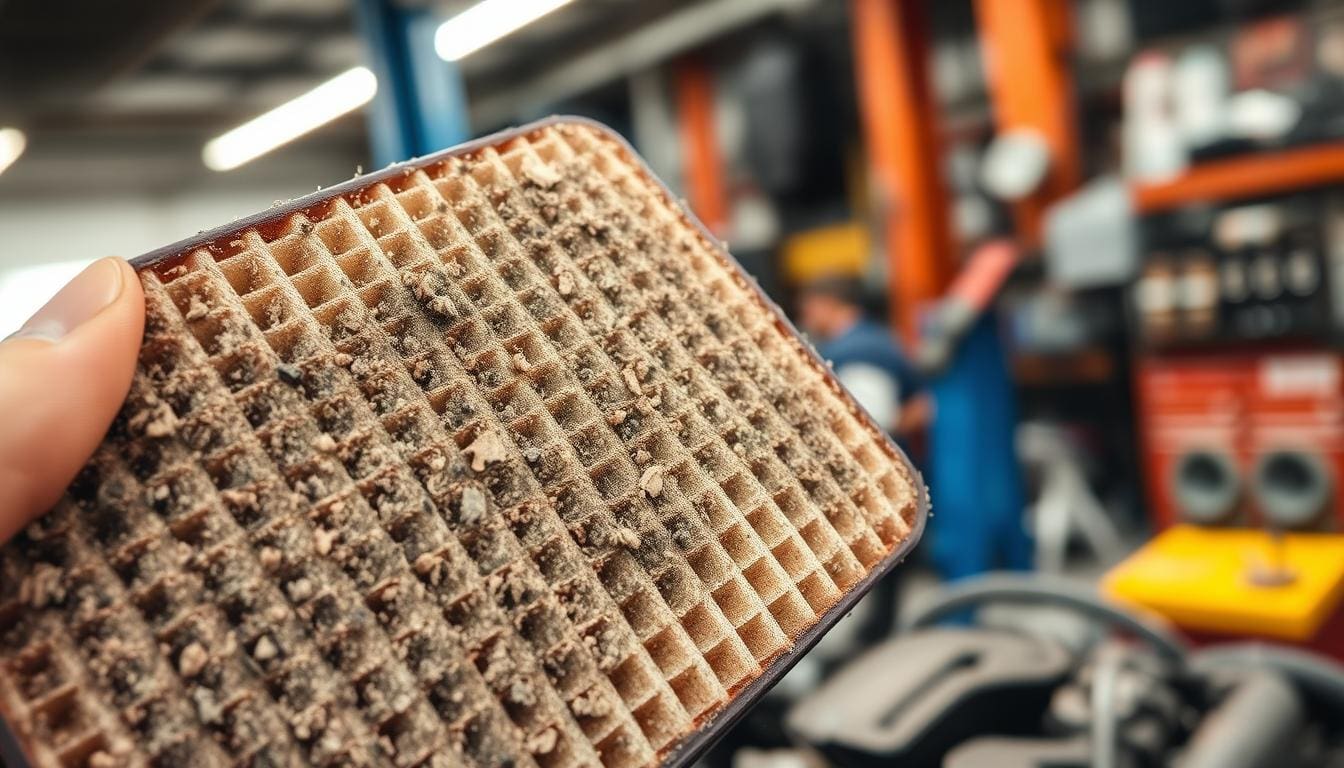

Visible dirt buildup when we inspect the old filter

When we remove old pleated elements, the pleats can be packed with dust and debris. Uneven dirt patterns often reveal sealing problems or bypassing at the edge.

- What we look for: packed pleats, edge bypass, and heavy dust loading.

- Practical step: remove old parts carefully and inspect before more costly diagnostics.

What an Air Filter Actually Does and Why Filtration Efficiency Matters

Good media stops grit before it reaches sensitive engine parts while letting enough breath through for normal operation. We focus on two goals: protect moving parts from particles and keep sufficient flow so the engine runs efficiently.

Capturing dust and particles before they reach sensitive components

The core job is simple: trap dust and abrasive particles that cause wear. Even fine grit will accelerate component wear if it bypasses the media or a poor seal.

How higher filtration can help but must still maintain airflow

Higher capture ratings typically catch more particles, yet too much restriction cuts the engine’s breathing. Pleated media is common because it increases surface area. That design helps maintain flow while improving particle capture.

In short: the best choice balances capture and flow. Proper installation and a tight seal matter as much as the media’s rated efficiency. Without correct fit, even high-quality products fail to protect parts or sustain real-world air quality and system performance.

How Often We Recommend Checking and Replacing Your Filter

We set a simple schedule so routine checks don’t slip and small issues don’t become big fuel drains.

Monthly check routine and timing guidance

Check monthly — that quick habit catches heavy loading early and keeps performance steady.

Many thin 1-inch media items need attention every 1–3 months. Thicker pleated media can last up to six months under normal use. Translate those ranges into real-world action: inspect first, change when the element looks loaded.

Conditions that shorten service intervals

Driving on dusty roads, through construction zones, on unpaved lots, or in heavy stop-and-go traffic loads the media faster. Pets, spilled debris, and frequent short trips at home or work also accelerate wear.

Practical tips we use in the shop

- Inspect monthly and keep a log of the last filter replacement to track MPG trends.

- If visible loading or restricted flow appears, replace rather than stretch intervals.

- Use inspection plus conditions — not just a calendar — to decide timing.

“A quick look each month prevents surprises and helps maintain quality fuel economy.”

Choosing the Right Air Filter for Your Vehicle

We start with a simple rule: fit matters most. The correct filter size creates a tight seal so unfiltered flow cannot bypass the media.

Getting the correct size for a proper seal and fit

We confirm size by checking the vehicle application and by comparing the new part to the old one. That prevents gaps, warped housings, and sealing faults.

Balancing filtration and airflow for real-world efficiency

Higher capture can protect engine parts but may restrict airflow if the system can’t take denser media. We pick the right type that keeps drivability and MPG stable.

Understanding rating terms and why MERV doesn’t always apply

The minimum efficiency reporting value and merv rating are HVAC standards. They help for home furnace air and hvac system choices, but they don’t map directly to automotive tests.

“Choose the right type and size for your vehicle before shopping by rating alone.”

| Concern | What we check | Shop guidance |

|---|---|---|

| Seal & fit | filter size match, no gaps | Use OEM fitment or measured size |

| Media vs airflow | filtration vs restriction | Prefer moderate media that the system supports |

| Ratings | merv and efficiency reporting terms | Use as context, not sole selection criteria |

Air Filter Replacement

We begin every service by setting up a clean work area and staging tools so the intake stays protected. A tidy surface and a short open time for the housing reduce the chance that dirt or debris falls into the system.

Tools and prep we use to keep debris out of the intake

Quick prep matters. We keep a shop towel, a gentle vacuum or brief compressed-air bursts, and basic hand tools on hand. That allows us to clear the top of the housing and move fast without spreading dust into the unit.

How we remove old filters without contaminating the airbox

We remove old filter elements slowly and upright to prevent shaking loose particles. If the part is very dirty, we bag it immediately so it can’t shed back into the engine bay.

How we insert new filter correctly for maximum airflow

When we insert new elements, we confirm the perimeter seal seats evenly in the filter slot. Some housings include direction airflow markings; we follow those arrows so the media faces the right way.

Our goal on every job is clear: maintain clean filtration and uninterrupted airflow, not just swap a unit. A careful swap saves components and helps keep MPG steady.

Step-by-Step: How We Replace an Engine Air Filter the Right Way

This short procedure keeps contaminants out of the intake and ensures the vehicle breathes freely after service.

Locate and open the housing

With the engine off, we find the housing and open the filter slot or airbox. We release clips slowly and avoid prying on tabs so seals stay intact.

Remove old unit and note direction airflow

We remove old parts upright to stop dust from falling into the system. If arrows mark direction airflow, we note them and keep the old piece for size comparison.

Clean the housing before we insert new

We wipe the seat and vacuum loose debris. Gentle work prevents pushing grit deeper into ducts.

Seat the right part and confirm the seal

We compare gasket shape and size so the right air filter seats squarely. Then we press the perimeter down evenly so no corners fold.

Final check

We close the lid, secure every latch, and confirm unobstructed airflow. Set a reminder for your next inspection to keep MPG steady.

Common Air Filter Replacement Mistakes That Can Still Waste Gas

A new part does not guarantee better MPG if installation or selection is wrong. Small errors in size, orientation, or type can allow unfiltered flow or create excess restriction. That keeps the engine from breathing as intended and limits gains after service.

Wrong size and poor sealing

We see wrong-size units or mismatched gasket profiles that leave gaps. Dust trails, uneven loading, or a lid that won’t seat flush are telltale signs we look for.

Installed backward

When arrows mark direction airflow, installing the element the wrong way reduces effective flow and can warp the media. Always confirm orientation before closing the housing.

Choosing the wrong type for the system

More capture isn’t always better. Highly restrictive media that the engine cannot support lowers efficiency and may cut MPG even after a new unit is fitted.

| Mistake | How we spot it | Fix |

|---|---|---|

| Wrong size/gasket | dust past seal, uneven pleat loading | use correct OEM fit or measured match |

| Backward install | direction arrows ignored, poor fit | align arrows with flow, check seating |

| Overly restrictive type | reduced throttle feel, no MPG gain | choose moderate media rated for the vehicle |

“A correct part, installed the right way, is the only sure path to restored efficiency.”

Engine Air Filter vs Cabin Air Filter: What Affects MPG and What Affects Air Quality

Understanding the separate jobs of the engine element and the cabin unit helps prioritize service when MPG or cabin comfort suffer.

How cabin units relate to indoor air quality and interior comfort

Cabin units mainly protect the space you occupy. Good media capture dust, pollen, and odors so occupants notice cleaner indoor air right away.

Comfort improves with better circulation and fewer allergens on vents and surfaces. That’s the direct benefit of maintaining cabin media.

When a clogged cabin unit can indirectly impact efficiency through HVAC strain

A clogged cabin element forces the blower and hvac system to work harder to move air through vents. That extra load can increase fuel draw when the compressor runs.

For MPG concerns, we still check the engine element first. But weak vent flow or heavy blower effort tells us to inspect the cabin side too.

| Role | Main Effect | When to Service |

|---|---|---|

| Engine element | Directly affects breathing and MPG | Check for visible loading and loss of throttle response |

| Cabin unit | Improves indoor air quality and comfort | Service when vents blow weak or odor appears |

| HVAC system | Moves conditioned indoor air; strain raises load | Inspect when blower sounds strained or A/C runs longer |

Both elements matter: one for engine efficiency, the other for cabin comfort. A complete plan keeps MPG and indoor air quality at their best.

When to Have Us Inspect the Intake System Beyond the Filter

When drivability or economy fail to improve after a simple service, we inspect the full intake system to find the real cause.

Airbox seals, ducts, and sensors that can mimic a clogged unit

Loose clamps, cracked ducts, or a warped seal let unmetered flow or bypass occur. That can produce the same symptoms as a loaded element.

Sensors downstream may also report odd readings that look like a clogged component. Fuel trims and airflow reports can mislead you unless the whole path is checked.

How we verify the fix with a quick performance and airflow check

We inspect the airbox integrity, sealing surfaces, and duct alignment. Any dust downstream is a strong sign of bypass or poor sealing.

After repairs we run a short verification: throttle response, idle stability, and a basic airflow behavior check. That confirms real improvement in performance and shows the unit now works the right way.

| Component | Common symptom | Shop action |

|---|---|---|

| Airbox seal | uneven dust patterns, whistling | replace gasket, seat perimeter evenly |

| Ducts & clamps | loss of throttle feel, limp response | repair or replace cracked ducts, tighten clamps |

| Sensors (MAF/TPS) | erratic fueling, strange airflow reading | clean, test, or replace as required |

“We hunt the root cause, not just the obvious part swap, so the fix lasts and performance stays consistent.”

Conclusion

Consistent inspections, correct fit, and careful installation are the fastest ways to restore lost performance.

Keep a monthly check habit. Replace the element when pleats show heavy dust or reduced flow. Prioritize proper size and a tight sealing surface so unmetered flow cannot bypass the media.

Install with the orientation arrows aligned and the housing clean. A well-chosen product balances capture and flow so efficiency improves without added restriction.

If symptoms persist, we inspect the full intake system to find the root cause. Hire Heaven Automotive — we will perform the right air filter replacement, verify improved performance, and set a reminder for your next service.