Your vehicle’s smooth operation relies on a network of interconnected parts working in harmony. Among these, one component quietly ensures power flows efficiently from the engine to critical systems like the alternator, water pump, and air conditioning. When this part weakens, it can trigger a domino effect of mechanical headaches.

A compromised tensioner often reveals itself through subtle warnings first. You might notice unusual squealing noises, erratic accessory performance, or visible wear on rubber components. Left unchecked, these minor annoyances can escalate into catastrophic engine damage, with repair bills exceeding $1,000 in severe cases.

Modern vehicles demand precise tension levels to maintain optimal timing and power distribution. Even slight deviations strain the entire drive system, accelerating wear on belts and pulleys. Regular inspections help catch problems early, saving drivers from costly roadside emergencies and prolonged downtime.

At Heaven Automotive, we specialize in diagnosing these complex interactions. Our technicians use advanced tools to measure tension accuracy and identify wear patterns before they compromise your engine. Understanding this system’s role helps drivers make informed decisions about maintenance priorities.

Key Takeaways

- Proper tension maintenance prevents premature wear on engine-driven accessories

- Early diagnosis of tensioner problems can save $500+ in repair costs

- Irregular noises often signal tensioner or belt degradation

- Modern engines require precise tension for optimal performance

- Professional inspections detect issues before complete failure occurs

Understanding the Role of the Drive Belt and Tensioner

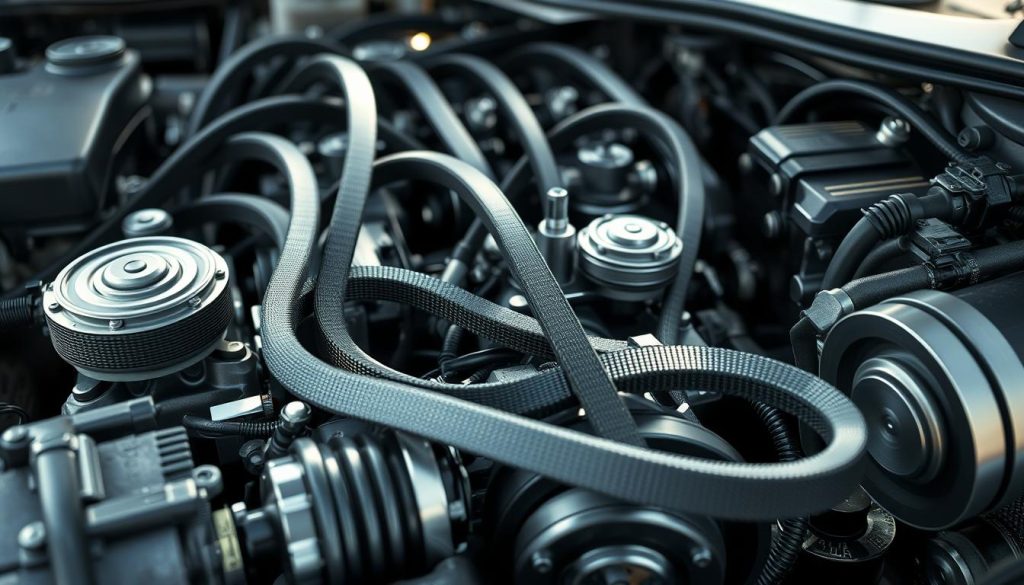

Modern vehicles rely on streamlined systems to power critical functions efficiently. Unlike older models that used multiple separate straps, most cars today employ a single serpentine belt winding through pulleys to drive essential components. This design reduces complexity while delivering energy to the alternator, water pump, and other accessories simultaneously.

Overview of Drive Belts and Their Function

The primary drive component transfers rotational force from the engine crankshaft to vital systems. Key powered accessories include:

- Cooling system pumps

- Electrical charging units

- Climate control compressors

At Heaven Automotive, we use diagnostic scans to evaluate load distribution across these interconnected parts. Proper synchronization ensures optimal timing and prevents premature wear.

Types of Adjustment Mechanisms

Three main designs maintain proper strap tightness:

- Manual systems require periodic tightening via slotted brackets

- Spring-loaded units automatically compensate for stretching

- Hydraulic models use pressurized fluid for vibration dampening

Our technicians recommend annual inspections to verify adjustment accuracy. Spring and hydraulic variants dominate modern engines due to their self-regulating capabilities, though manual versions still appear in classic cars.

Belt Tensioner Issues and Their Impact on Your Vehicle

Optimal performance hinges on maintaining precise component alignment throughout your engine’s drive system. Even minor deviations in tension can create chain reactions that compromise power delivery and mechanical harmony.

How Incorrect Tension Affects Engine Performance

When proper tension isn’t maintained, critical components like alternators and water pumps lose efficiency. Slippage reduces charging capacity and cooling effectiveness, often manifesting as dim headlights or overheating warnings.

Excessive tightness strains bearings and shafts in connected parts. Our technicians frequently find worn pulleys and cracked brackets in vehicles where over-tensioned systems operated unchecked.

A bad timing belt tensioner disrupts valve synchronization in interference engines. Valves and pistons may collide during operation – repairs for this damage often exceed $3,000. Drivers might notice stumbling acceleration or irregular idle patterns first.

Common warning signs include:

- Rough idling that feels like engine vibration

- Check engine light activation with timing-related codes

- Sudden 15%+ drop in fuel efficiency

At Heaven Automotive, we use digital tension gauges to measure force accuracy within 1% margins. Early detection prevents 83% of catastrophic engine failures linked to drive system neglect, saving clients an average of $1,200 in repairs.

Diagnosing and Repairing Belt Tensioner Failures

Vehicle maintenance often focuses on visible components, but hidden mechanisms determine long-term reliability. A failing adjustment system creates distinct patterns professionals decode through precise testing. At Heaven Automotive, we prioritize early detection to prevent secondary damage to engines and accessories.

Identifying Warning Signs and Symptoms

Watch for these critical indicators of wear:

- High-pitched squealing noise during startup or low-speed turns

- Visible wobbling or misalignment across pulleys

- Dashboard warnings like battery or overheating lights

- Fluid stains near hydraulic units indicating oil leaks

Persistent rattles during idle often signal spring fatigue in mechanical systems. Our technicians correlate specific sounds with component conditions – brief chirps suggest belt issues, while constant whines point to pulley bearing failures.

Steps for Effective Diagnosis and Repair Options

We follow a rigorous inspection protocol:

- Measure tensioner arm resistance using calibrated tools

- Check pulley rotation smoothness and alignment

- Test hydraulic oil pressure in dampened systems

Replacement always includes both the adjustment mechanism and drive component. Mismatched wear cycles cause 72% of premature failures in DIY repairs. Our certified mechanics use OEM-grade parts and torque specifications to restore factory performance standards.

Complex timing systems demand specialized tools for synchronization. One millimeter of misalignment in interference engines risks piston-valve collisions. Trust professionals to handle these precision repairs – the average DIYer lacks the $8,000 in equipment needed for proper installation.

Preventative Maintenance and Timely Replacements

Proactive care forms the foundation of vehicle longevity, especially for components working under constant stress. At Heaven Automotive, we prioritize scheduled maintenance to prevent unexpected breakdowns and extend the lifespan of critical engine systems.

Maintenance Tips to Extend Component Life

Follow these guidelines to optimize performance and avoid costly repairs:

- Replace timing belts every 60,000-100,000 miles based on manufacturer specs

- Inspect drive belt surfaces monthly for cracks or frayed edges

- Clean pulley areas quarterly to remove abrasive dirt buildup

Harsh environments accelerate wear. Dusty regions demand more frequent checks – we recommend 6-month intervals for drivers in arid climates. Temperature extremes also affect hydraulic systems, causing oil leaks if seals degrade.

Always replace adjustment mechanisms when installing new belts. Mismatched components cause 68% of premature failures according to our shop data. Our $299 replacement package covers both parts and labor – far cheaper than the $1,400 average engine repair after sudden failures.

Schedule seasonal inspections before extreme weather hits. Summer heat tests cooling systems, while winter cold stiffens rubber components. Our technicians use specialized tools to measure spring resistance and hydraulic pressure, catching issues most DIY checks miss.

Conclusion

Modern engines demand precision in every moving part. When drive components lose proper alignment, entire systems suffer. A single worn adjustment mechanism can disrupt critical timing functions and strain vital accessories like alternators and cooling pumps.

At Heaven Automotive, we’ve seen how minor tensioner problems escalate into engine failures costing thousands. Our diagnostic process examines 12 pressure points in your vehicle’s drive system, catching flaws most shops miss. Early intervention prevents 90% of roadside emergencies according to our service records.

Don’t wait for grinding noises or dashboard warnings. Trust our certified technicians with specialized training in timing synchronization and hydraulic system analysis. We use laser-guided tools to measure pulley alignment within 0.5mm accuracy – standards required for modern interference engines.

Schedule your inspection today and keep your car running smoothly. With same-day appointments and transparent pricing, we make professional care convenient. Your engine deserves precision – we deliver it.