We at Heaven Automotive explain how a vehicle climate system keeps you comfortable and your car running well.

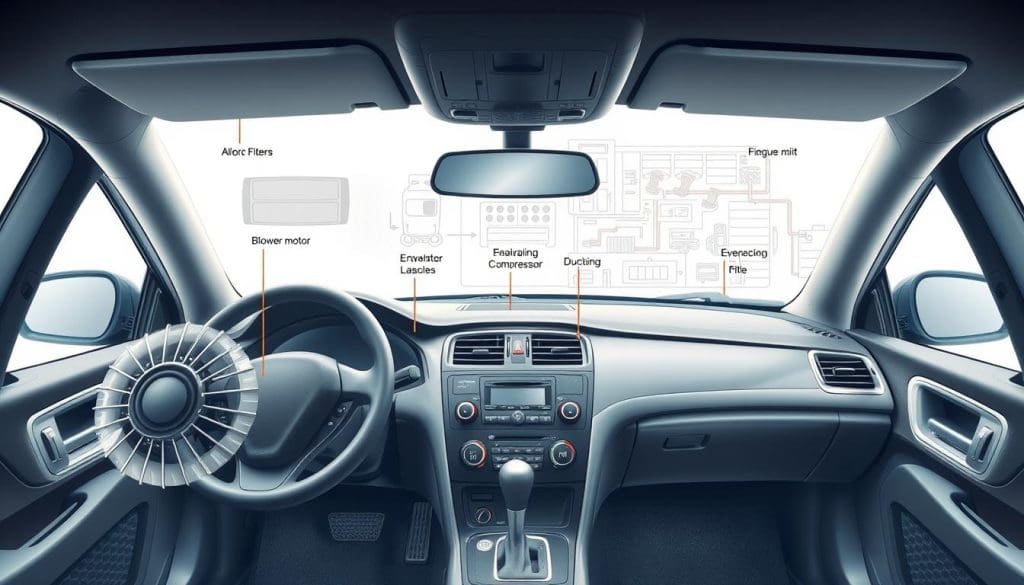

Think of the system as a set of parts that move heat, manage airflow, and respond to controls. It blends air conditioning, heating, vents, and electronics into one working unit.

Our approach treats HVAC diagnostics as a structured process, not guesswork. Charts and quick checks help technicians compare temperatures and pressures. Those tools speed troubleshooting, but they are only a starting point.

We focus on practical, visible signs: vent output, air temperature, control behavior, and component response. We start with least-invasive checks to save time and avoid unnecessary parts replacement.

In this guide we will show how heat moves, which components we inspect, common symptoms, and our shop workflow. At the end, we invite you to hire Heaven Automotive when DIY checks stop being productive.

Key Takeaways

- Automotive climate control blends air conditioning, heating, airflow, and controls into one system.

- We use charts and targeted checks to narrow causes quickly, but confirm with tests.

- Same symptom can come from different parts—structured troubleshooting matters.

- We begin with noninvasive tests to protect your time and wallet.

- Contact Heaven Automotive for professional service when problems go beyond basic checks.

How an Automotive Climate Control System Moves Heat Where We Want It

Heat transfer and airflow are the two simple ideas that make the whole climate system work. We look at heating, cooling, and the air paths that deliver temperature to the cabin. Understanding these basics helps us test the right parts without guesswork.

Heating mode basics

In heating, engine coolant carries heat to the heater core. The core warms passing air, and the blend door mixes that warm air with cooler air to reach the driver’s setting.

Thermostats and temperature sensors affect warm-up time and steady heat. Weak heat at idle or fluctuating output often ties back to warm-up logic, blend door operation, or coolant flow.

Cooling mode basics

Cooling is a closed loop where refrigerant absorbs heat at the evaporator inside the dash and rejects it at the condenser outside the radiator area. Both components must work for cold air at the vents.

“If the condenser can’t shed heat, high-side pressure rises and cooling drops even when the compressor runs.”

Ventilation and airflow paths

Airflow matters as much as temperature change. Fresh-air intake, recirculation, and vent selection control where cooled or heated air goes.

Recirculation often cools faster on hot days. Fresh air helps clear odors and reduce window fog. Blocked ducts or a stuck mode door can mimic a refrigerant-side failure, so we always check airflow before charging the system.

- Key idea: what you feel at the vents is the result of heat exchange plus airflow delivery.

Core Components We Inspect During HVAC diagnostics

Our team methodically checks every component that moves air and heat to find the real cause. We prioritize simple confirmations first so we do not mislead repair choices.

Compressor checks and control signals

Compressor function goes beyond seeing it spin. We verify clutch engagement, control-module commands, and whether the unit is allowed to run under current conditions.

Condenser condition and fan performance

We inspect condenser fins, look for blockage, and test cooling fan output at idle and in traffic. Poor fan airflow often causes high pressure and weak cooling.

Evaporator performance and drain concerns

The evaporator must transfer heat and remove moisture. A refrigerant leak or blocked drain can cause coil icing, musty smells, or wet carpets.

Blower motor, control module, and airflow delivery

Weak or missing blower speeds often mimic low cooling. We test the motor, resistor or module, and measure vent output before changing refrigerant.

Thermostat logic and sensing

Control heads, ambient sensors, and actuators guide temperature decisions. A biased sensor can make the system think the cabin already reached the set temperature.

Filters and debris

We treat cabin filters as a high-impact, low-cost check. A clogged air filter chokes airflow and reduces evaporator heat exchange, often mimicking larger problems.

Symptoms That Signal a Climate Control Issue

Drivers notice problems first by what they feel at the vents and the sounds the system makes. These clues tell us whether the fault is simple or needs shop testing.

Insufficient cooling or weak heat

Insufficient cooling often maps to four categories: airflow restrictions, condenser airflow problems, low refrigerant or leaks, and control strategies that limit compressor run time. Warm vent air, poor performance, or slow recovery suggest one of these.

Weak heat usually points to heater core transfer, blend door behavior, or thermostat and sensor logic that misread temperature.

Short cycling and intermittent operation

Short cycling—when the system turns on and off rapidly—often stems from control signals, sensor feedback, or changing thermal load. Dirty filters, a frozen evaporator, or low refrigerant can trigger this behavior.

Noises, smells, and moisture clues

Clicking, whooshing, or fan contact should be checked for loose fasteners or fan interference first. Musty or “dirty sock” odors mean moisture and drain problems or a dirty evaporator. Burning or exhaust-like smells need immediate service.

“If a symptom costs you time or energy, let us test it rather than guess.”

Our Step-by-Step HVAC Troubleshooting Workflow in the Shop

Every service visit begins with fast checks that save time and prevent needless teardown. We follow a clear, repeatable process so technicians reach the correct fix on the first visit.

Start with quick checks

We verify settings, obvious damage, and whether the complaint is steady or intermittent. These quick checks often remove guesswork and cut repair time.

Electrical first

We confirm power, fuses, relays, commanded states, and stored error codes. A bad module or blown fuse can change the entire troubleshooting direction.

Airflow next — “Air Before Charging”

Airflow checks include cabin filters, duct restrictions, vents, and blower speed. Restricted air skews refrigerant readings, so we correct airflow before any charge work.

Refrigerant charge last

Only after electrical and airflow checks do we measure pressures and temperatures and compare them to vehicle specs. Charts guide us but never replace verification.

“Diagnostic charts are a starting point; we confirm with real vehicle tests.”

| Quick Check | What We Look For | Why It Saves Time |

|---|---|---|

| Controls & Settings | Correct temperature and mode | Avoids unnecessary parts work |

| Electrical | Power, fuses, relays, codes | Rules out control faults early |

| Airflow | Filters, vents, blower output | Prevents misreading refrigerant data |

We finish with a performance check using delta‑T across the evaporator and, when needed, superheat/subcool testing. The result is a documented, step-by-step workflow that gets the system back to spec and restores comfort.

Common Problems We Find and the Fix That Restores Comfort

Most comfort complaints trace to a few repeating faults we see on the bench and on the road. We group causes so repairs target the source, not the symptom.

Low refrigerant or leaks

Low refrigerant reduces cooling capacity and can let the evaporator ice up in certain conditions. Restoring comfort means finding and repairing the leak, then charging the system to spec.

Airflow restrictions

Clogged filters, leaves, and other debris on coils cut airflow and reduce heat transfer. We replace filters, clear debris, and fix blower or duct faults so the system moves proper air across heat exchangers.

Thermostat and control faults

Biased sensors, calibration errors, or failed actuators create odd temperature swings. We test sensors and actuators and calibrate controls before recommending costly parts swaps.

Condenser-side issues

Blocked fins, crushed passages, or weak fan output hurt heat rejection and drop performance in traffic or hot weather. Cleaning, straightening, or fan repair restores proper cooling and efficiency.

Why correct diagnosis matters

Replacing parts without testing often leaves the original problem. We verify repairs with airflow and temperature checks so the system truly performs.

“A verified fix beats a hopeful parts change every time.”

Conclusion

Real fixes come from measured temperature and airflow checks, not hopeful parts swaps.

Comfort in a vehicle depends on heat transfer, airflow, and controls working together in one system. We diagnose the full circuit so a single symptom does not lead to the wrong repair.

Our shop order stays the same: electrical checks first, airflow inspection next, and refrigerant-side testing last. That sequence saves time and prevents repeat visits.

Filters, duct delivery, and condenser airflow are frequent root causes. We verify performance with vehicle‑specific temperature readings and documented tests before we call a job complete.

Charts and rules of thumb start the process, but only confirmed tests finish it. Hire Heaven Automotive for professional service and restore reliable comfort the first time.