Every driver notices when a ride changes. Worn components make bumps feel harsher, add extra bounce, and reduce control. These shifts matter on daily commutes in san antonio, where stop-and-go streets and quick turns test every system.

We explain how wear alters what you feel and why a healthy system keeps the vehicle stable during braking and cornering. A well-maintained setup keeps tires in consistent contact with the road for better handling.

Our service page shows common symptoms, which parts usually wear out, how we diagnose issues, and which fixes restore control. Ignoring early signs speeds tire wear and can lead to alignment problems and higher costs later.

At Heaven Automotive, we offer a straightforward, safety-first inspection and the guidance drivers need to decide on professional help. Follow our simple path: recognize symptoms, schedule an inspection, confirm the cause, complete necessary work, and protect tires with alignment when needed.

Key Takeaways

- Wear changes ride feel and reduces control.

- A healthy system improves handling and braking.

- Early diagnosis prevents faster tire wear and extra costs.

- Heaven Automotive provides clear, safety-first inspections.

- Next steps: spot symptoms, book inspection, fix root causes.

Why Your Vehicle Suspension System Matters for Comfort and Control

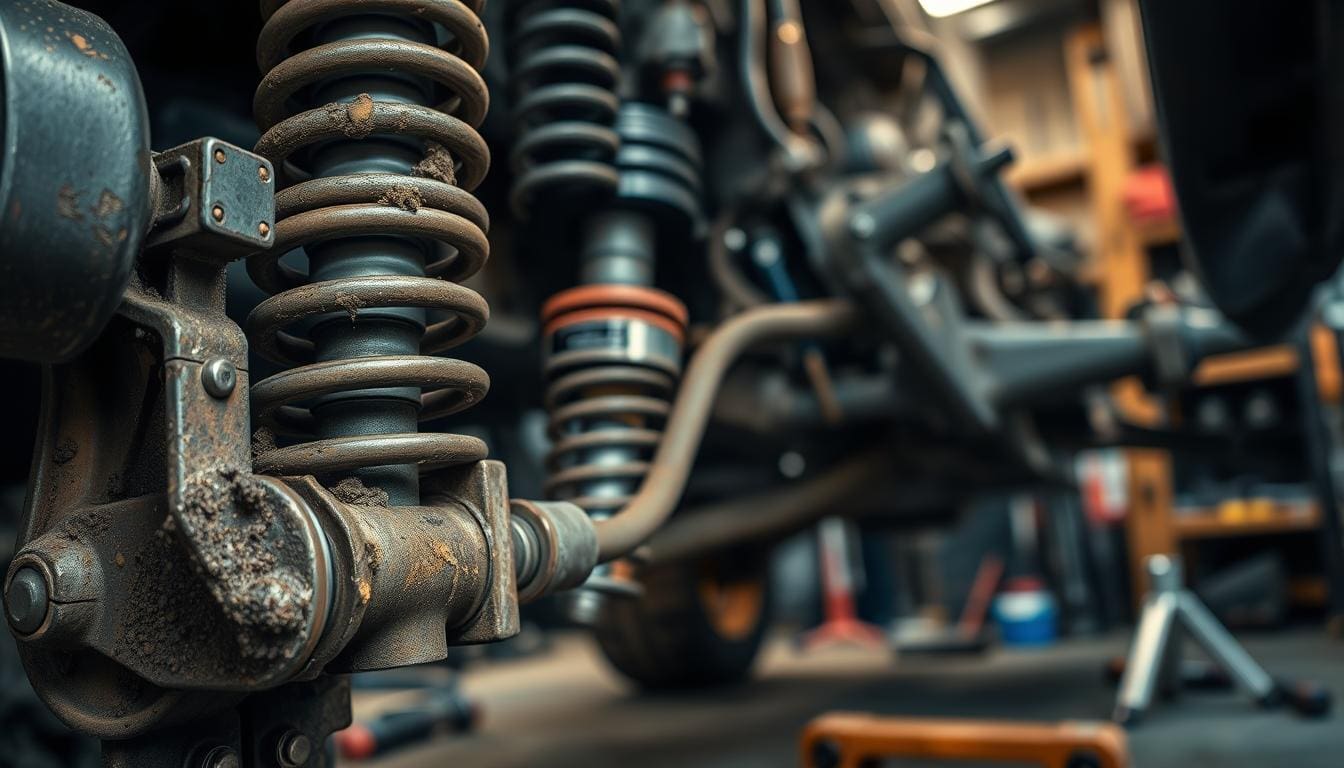

When key parts work together, your drive stays composed over rough pavement and quick turns. We focus on how the vehicle suspension system balances weight, cushions impacts, and keeps tires planted so handling and braking feel predictable.

How the system keeps tires in contact for better handling and braking

Consistent tire contact means better grip and shorter, steadier stops. Proper damping prevents wheel hop and helps the steering respond the same way every time you turn the wheel.

How worn components reduce ride quality on rough roads

Rough roads and potholes speed up wear in bushings, joints, and dampers. Small failures add up, and the ride becomes harsher or more floaty over time.

Comfort complaints often signal control issues, not just annoyance. We recommend an inspection so we can keep your driving experience comfortable and controlled. At Heaven Automotive, we inspect, explain, and help you decide the right next steps to keep vehicle systems working as designed.

How Suspension Wear Creates Safety Risks Behind the Wheel

Worn components change how a vehicle reacts in urgent moments, turning routine braking or a quick lane change into a safety risk.

Longer stopping distances and nose-dive during braking

Reduced damping lets the front end dip sharply under braking, a behavior often called nose-dive.

This forward weight transfer can lengthen stopping distance and make emergency stops less stable.

Swaying, drifting, or “floating” in turns

A vehicle that sways or feels like it floats loses precise handling at speed.

That instability raises the chance of overcorrection or losing a lane during quick maneuvers.

Steering response changes and wandering

Loose linkage or worn mounts change steering feel and cause wandering that forces constant corrections.

Driver fatigue grows and the risk of erratic driving increases when steering response is inconsistent.

- Why it matters: These defects affect safety, not just comfort.

- How it shows up: Symptoms often appear slowly, so drivers adapt without noticing.

- What to do: If you feel any of these signs today, schedule an inspection with us at Heaven Automotive.

| Symptom | Immediate Risk | Likely Causes | Recommended Action |

|---|---|---|---|

| Nose-dive when braking | Longer stopping distance | Worn dampers or mounts | Inspect dampers; replace if weak |

| Swaying or floating in turns | Reduced stability at speed | Worn bushings, springs, or links | Full steering and suspension check |

| Wandering or loose steering | Erratic lane control | Tie rods, rack wear, alignment | Steering evaluation and alignment |

Common Signs You Need Suspension Service Today

When the ride starts feeling rougher or the car bounces more than usual, it’s a strong hint something needs attention. We aim to help you spot clear, customer-friendly signs so you know when to schedule a professional service.

Excessive bouncing and a harsher driving experience

Excessive bounce after bumps that doesn’t settle quickly means damping is weak. That change hurts comfort and steady handling.

Noises, vibrations, and clunking

Clunks, squeaks, or steady vibrations often point to worn mounts, bushings, or joints. If noises increase at speed, those are real issues to check.

Uneven tire wear and rapid tread loss

Cupping or inside/outside tread wear shows affected components. Uneven tire wear shortens tire life and signals worn parts that need inspection.

Pulling, off-center wheel, and alignment-related issues

Pulling to one side or an off-center wheel usually ties to alignment-related issues. Worn steering parts can cause the same symptoms.

If symptoms worsen, happen at speed, or appear with tire wear, stop guessing and book a full inspection with us. We confirm causes and recommend lasting suspension services so steering and ride feel return to normal.

What Wears Out First in a Suspension System

Wear often starts at the connections that link wheels to steering, not the big parts you see at a glance. Mileage, driving style, and rough roads make certain parts fail sooner.

Shocks vs. struts and why they can’t replace each other

Shocks and struts both control bounce, but a strut also supports the vehicle’s weight. A wheel has either a shock or a strut — never both — so a shock cannot be swapped for a strut and vice versa.

Look for fluid leaks, damaged housings, worn mounts, persistent bounce, or brake dive as clear failure clues.

Ball joints and control arm wear

Ball joints connect the control arm to the steering knuckle. When they loosen, stability drops and tire wear becomes uneven. That looseness is an early sign we check closely.

Tie rods, rack and pinion, and steering linkage

Tie rods link the rack and pinion to the wheel knuckle. Play here causes wandering and constant correction. If steering feels loose, the rack and pinion may be the source.

CV joints, axles, and clicking when turning

Clicking while turning often points to worn CV joints or axles on front-wheel drive cars. Addressing this early prevents added damage to other components.

We diagnose which part is truly worn rather than guessing. Bring your car to us and we’ll confirm the failing components and recommend the right course of action.

Suspension Repair San Antonio: Our Inspection and Diagnostic Approach

Our diagnostic process begins with a careful visual and hands-on inspection to find the real cause, not just the loudest symptom. At Heaven Automotive we use a stepwise method so recommendations match what the vehicle actually needs.

Comprehensive steering and suspension evaluation

We check joints, bushings, mounts, and linkages for play, cracking, or looseness. Our technicians physically test components to reveal hidden wear.

Fluid leaks and damaged hardware

Shocks and struts can leak or lose damping. We inspect mounts and fasteners because worn mounts often mimic larger failures and worsen ride comfort.

Road-test symptoms we document

On a controlled drive we note bounce after bumps, brake dive, sway in turns, and handling changes at speed. These behaviors guide our diagnosis and help prioritize work.

Tire wear and alignment data

We compare tire patterns like cupping or rapid tread loss to wheel alignment readings. Modern alignment equipment helps us determine if pulling or off-center wheels are alignment-only or caused by worn parts.

Clear communication: we share findings, explain safety risks, and outline urgent versus scheduled fixes. That way you can choose the right path for cost and safety.

| Step | What we check | Why it matters |

|---|---|---|

| Initial inspection | Joints, bushings, mounts | Finds play or cracking that affects steering |

| Leak check | Shocks/struts, seals | Identifies lost damping and ride issues |

| Road test | Bounce, brake dive, sway | Reproduces symptoms to confirm cause |

| Alignment & tire review | Wheel angles, tire wear | Distinguishes alignment issues from worn parts |

Repairs and Services We Provide to Restore Ride Quality

Our team offers targeted services that return comfort and control to your daily drive. We focus on correct parts, skilled installation, and road testing so fixes last under real conditions.

Shock and strut replacement

Shocks and struts reduce bouncing, steady the vehicle in turns, and limit front-end dive during braking. Replacing worn units improves comfort and braking control right away.

Ball joint and tie rod service

Ball joints and tie rods correct looseness and steering play. Tightening or replacing these parts restores straight-line tracking and sharper steering response.

Rack and pinion service

When steering feels loose or inconsistent, we inspect the rack and pinion and related linkages. Our expert work returns predictable steering feel and reduces wandering.

CV joint and axle service

Clicking or popping during turns often means worn CV joints or axles. We replace failing components to stop noise and prevent further drivetrain damage.

Wheel alignment to protect tires

Wheel alignment is standard after most steering and suspension services. Correct geometry helps prevent uneven tire wear and extends tire life.

Quality matters: we use quality parts, follow manufacturer specs, and verify results with a road test and final inspection.

| Service | What it fixes | Benefit |

|---|---|---|

| Shocks & struts | Excess bounce, brake dive | Improved comfort and stability |

| Ball joints & tie rods | Steering play, wandering | Sharper tracking and control |

| Rack and pinion | Loose or inconsistent steering | Predictable steering feel |

| CV joint & axle | Clicking in turns | Quieter, safer turning |

| Wheel alignment | Uneven tire wear | Longer tire life and correct tracking |

If your car is bouncing, pulling, or wearing tires quickly, schedule an appointment with Heaven Automotive for an inspection and estimate. We’ll recommend the right services and timeline for quality results.

When to Schedule Suspension Repair and How Often to Check It

Catching wear early keeps driving safe and saves money over time. We recommend a routine check to spot issues before they become failures.

Why annual or ~12,000-mile inspections make sense

Check yearly or around every 12,000 miles to catch worn parts early. In San Antonio, potholes, uneven pavement, and stop-and-go streets speed wear.

Regular checks help us find problems that shorten tire life or cause steering play. That proactive step helps keep vehicle handling predictable.

Lifespan expectations and triggers for earlier checks

Shocks and struts often last 50,000–100,000 miles, but rough road exposure, heavy loads, or aggressive driving can shorten that range.

- Hard pothole hits, curb impacts, or sudden pulling are trigger events to inspect sooner.

- New or rapid tire wear and steering changes also call for an immediate check.

- Early intervention protects tires, steering parts, and lowers long-term costs.

If it’s been a long time since your last check, now is the right time to schedule an appointment with us. Call to book an appointment and let our team keep your vehicle safe on the road.

Conclusion

What begins as extra bounce or noise can become longer stops and wandering steering if left unchecked. Suspension wear often starts as a comfort issue and quickly becomes a safety concern.

Watch for bouncing, clunking, pulling, an off-center wheel, or rapid tire wear. These signs point to worn shocks/struts, steering linkage, alignment faults, or failing CV joints.

Diagnosis matters: overlapping symptoms require a trained eye to find the root cause and recommend the proper fix. Timely suspension repair protects tires, restores control, and improves confidence on local roads.

If you notice these issues today, hire Heaven Automotive. Our technicians will inspect your vehicle, explain findings, and deliver the right services for a safer, smoother drive.