Few things feel worse than discovering your home’s cooling system isn’t working during a heatwave. While many air conditioner issues are minor, problems with the central mechanical component—your compressor—can lead to expensive repairs. Recognizing early warning signs helps you avoid sudden breakdowns and costly replacements.

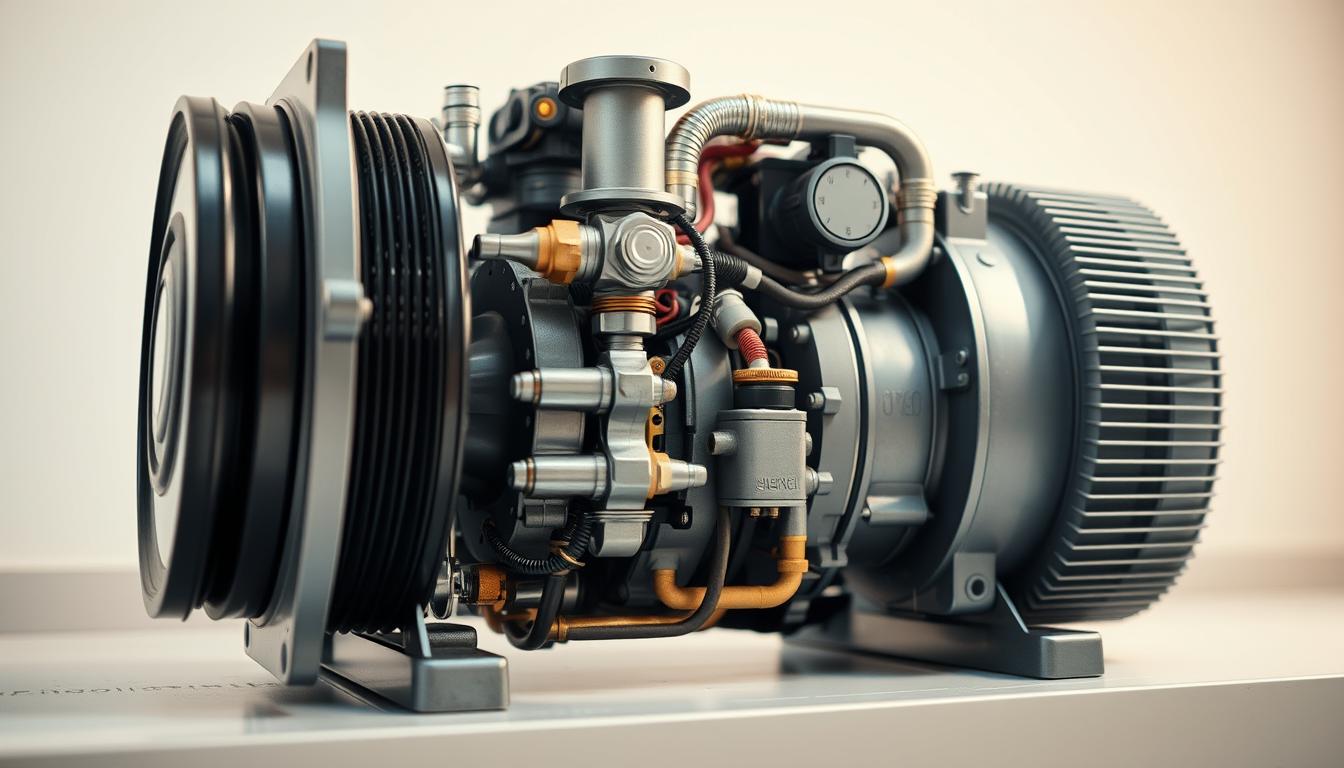

Your compressor acts as the “heart” of your HVAC system, circulating refrigerant to keep your space comfortable. When this part starts failing, you might notice warm air blowing from vents, unusual noises, or frequent system cycling. These symptoms often develop gradually, giving homeowners time to act before a full failure occurs.

With proper care, compressors typically last 10–15 years. However, dust buildup, refrigerant leaks, or electrical issues can shorten this lifespan. The average replacement cost hovers around $1,200, making prevention through regular maintenance crucial. Simple steps like cleaning coils and scheduling professional inspections can save thousands in repair bills.

Key Takeaways

- Compressor replacements average $1,200, emphasizing the value of early detection

- Most failures develop slowly over weeks or months

- Unusual noises and weak airflow signal potential compressor trouble

- Annual maintenance extends equipment life by 30–50%

- Refrigerant leaks accelerate wear on critical components

At Heaven Automotive, our certified technicians specialize in diagnosing and resolving compressor issues before they escalate. We provide transparent assessments and prioritize cost-effective solutions to keep your cooling system running smoothly. Contact us today to schedule an inspection and protect your home comfort.

Understanding the Role of Your AC Compressor

Your home’s comfort depends on a component often called the “heart” of temperature control. Located in the outdoor unit, this part drives refrigerant through the entire setup to remove warmth from indoor spaces. Without it, heat transfer stops completely.

How This Component Operates

The process starts when cold refrigerant absorbs indoor warmth through the evaporator coil. As the substance turns into gas, it travels to the outdoor unit. Here, specialized machinery pressurizes the gas, significantly raising its temperature.

This superheated vapor then moves to the condenser coil. Outdoor air cools the refrigerant back into liquid form, releasing captured heat. The cycle repeats continuously to maintain your preferred indoor climate.

The Value of Consistent Care

Constant exposure to high-pressure conditions and temperature extremes strains even durable equipment. Dirt accumulation or lubrication issues can accelerate wear. Our team at Heaven Automotive uses advanced diagnostics to spot early signs of trouble during seasonal checkups.

Regular servicing ensures proper refrigerant levels and electrical connections. These steps help prevent 80% of common operational issues. We prioritize extending equipment lifespan while optimizing performance for year-round reliability.

Warning Signs of AC Compressor Failure

Spotting mechanical issues early can mean the difference between affordable repairs and full system replacements. Three key indicators often reveal developing problems in temperature control equipment. Addressing these promptly helps maintain home comfort while preventing unexpected breakdowns.

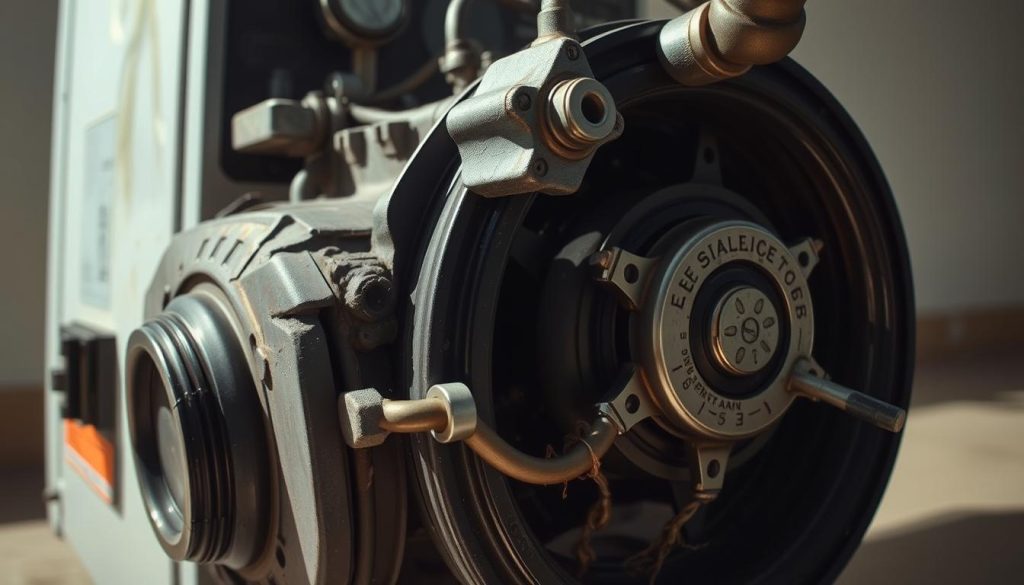

Reduced Cooling Power and Strange Sounds

Weak airflow through vents often signals struggling equipment. When systems push warm or minimal air despite proper settings, internal components may be wearing out. This symptom frequently appears before complete shutdowns occur.

Metallic clanking or grinding noises from outdoor units demand immediate attention. These sounds suggest loose parts or damaged internal mechanisms. Ignoring them often leads to irreversible component damage.

Energy Waste and Electrical Concerns

Unexplained spikes in power bills frequently accompany failing mechanical systems. Overworked equipment consumes extra electricity while delivering poor results. Homeowners typically notice this pattern over 2-3 billing cycles.

Frequent circuit breaker trips indicate dangerous electrical overloads. When systems draw excessive current, safety mechanisms activate to prevent fires. This warning requires professional diagnosis within 48 hours.

We recommend scheduling inspections if multiple symptoms appear simultaneously. Our technicians use thermal imaging and pressure tests to pinpoint developing issues. Early intervention typically cuts repair costs by 40-60% compared to emergency replacements.

Common Causes Behind Compressor Problems

Mechanical systems rarely fail without warning. Most issues stem from preventable maintenance gaps or environmental factors that strain components over time. Let’s explore three primary culprits behind performance declines in climate control equipment.

Electrical Issues and Heat Traps

Faulty wiring and corroded connections create acid buildup that eats away at internal parts. Blocked condenser coils covered in dirt act like thick blankets, trapping heat and forcing your equipment to work overtime. Debris around outdoor units restricts airflow, leading to dangerous overheating cycles.

Refrigerant Imbalances

Low refrigerant levels from undetected leaks reduce pressure, making components strain to maintain cooling power. Conversely, overfilled systems create excessive pressure that damages valves and seals. Both scenarios push equipment beyond safe operating limits.

Lubrication Breakdowns

Insufficient oil circulation lets metal parts grind together, generating destructive friction. Clogged suction lines disrupt refrigerant flow while displaced evaporator motors force oil out of critical areas. These issues often develop silently until major damage occurs.

We recommend professional inspections every six months to catch these problems early. Our technicians use ultrasonic leak detectors and thermal scanners to identify risks before they escalate, preserving your system’s health and efficiency.

Preventative Tips to Avoid Compressor Breakdown

Smart maintenance habits protect your home’s cooling investment better than reactive repairs. We’ve seen countless systems fail prematurely due to overlooked care routines – and we want to help you avoid that outcome.

Proper Lubrication and Cleaning Practices

Dusty coils and low oil levels force your equipment to work overtime. Clean the outdoor unit monthly during peak seasons using a soft brush or garden hose. Trim plants within two feet to prevent airflow blockages.

Lubrication checks require expertise – our technicians verify oil viscosity and pump function during bi-annual inspections. Never attempt refrigerant handling yourself, as incorrect pressure adjustments can damage valves.

Relying on Qualified HVAC Professionals

DIY fixes often worsen underlying issues. Licensed experts use thermal cameras to spot overheating wires and test for acid buildup in electrical panels. They also:

- Clear suction line obstructions

- Install voltage monitors

- Flush condenser coils

Surge protectors shield sensitive components from power spikes. Schedule professional cleanings every six months to maintain peak efficiency. Remember – proper care today prevents 80% of emergency breakdowns tomorrow.

Book seasonal maintenance now to keep your system running smoothly for years. Our team at Heaven Automotive provides thorough 25-point inspections that catch issues before they escalate.

Cost Implications and Repair Considerations

Financial planning for climate control equipment issues requires understanding two critical factors: repair viability and long-term value. While maintenance costs seem manageable upfront, major component replacements demand careful budgeting. Professional assessments often reveal whether temporary fixes or full upgrades make economic sense.

Understanding Repair and Replacement Expenses

Replacing critical components averages $1,200 but varies widely. These factors influence final costs:

- Equipment age and compatibility

- Refrigerant type requirements

- Labor rates in your region

- Warranty coverage status

Units older than 10 years often face diminishing returns on expensive repairs. Newer models with sealed refrigerant systems might need specialized handling. We recommend comparing repair quotes against replacement estimates when facing major issues.

Seasonal maintenance contracts typically cost 15-20% of emergency service calls. Our technicians prioritize cost-effective solutions, whether adjusting refrigerant levels or recommending energy-efficient upgrades. Early detection through routine checks prevents 60% of catastrophic breakdowns.

Invest in quality parts and certified labor despite higher initial costs. Bargain repairs using incompatible components often lead to repeat issues. Trust professionals who provide transparent warranties and performance guarantees for lasting results.

Conclusion

Protecting your home from unexpected breakdowns starts with understanding your cooling system’s needs. Regular maintenance and early detection of issues like refrigerant leaks or airflow restrictions can prevent 70% of common operational problems. Ignoring unusual noises or gradual performance declines often leads to irreversible component damage.

Proper lubrication and balanced pressure levels keep mechanical parts working smoothly. Dirty coils or blocked lines force systems to overcompensate, generating excess heat that strains critical components. We recommend checking your outdoor unit monthly for debris buildup during peak cooling seasons.

At Heaven Automotive, our 25-point inspections identify risks like acid corrosion or worn electrical connections before they escalate. Seasonal maintenance plans ensure optimal temperature control while extending equipment lifespan. Addressing minor concerns promptly saves time and money compared to emergency repairs.

Don’t wait for complete system failure to act. Schedule a professional evaluation today to maintain your home’s comfort and efficiency year-round. Our team provides clear solutions tailored to your equipment’s unique needs, helping you avoid costly replacements down the line.