Your car relies on a network of components to run smoothly, and few parts work harder than the system that keeps your motor securely in place. These critical connectors absorb vibrations, reduce noise, and prevent excessive movement during acceleration or rough terrain. When they wear out, even minor issues can escalate into major repairs.

Most vehicles use two to four of these anti-vibration parts, creating a balanced setup that protects sensitive equipment. Over time, constant stress from heat, road conditions, and engine torque can weaken their structure. Ignoring early symptoms often leads to misalignment, strained wiring, or even cracked transmission housings.

We recommend paying attention to unusual noises or shifts in driving feel. A failing system doesn’t just compromise comfort – it risks damaging other vital mechanisms. Catching issues early helps avoid costly fixes down the road while keeping your ride stable and safe.

Key Takeaways

- Critical connectors stabilize your motor and minimize vibrations during operation

- Most cars have multiple units working together as a protective system

- Worn parts can cause cascading damage to surrounding components

- Early detection prevents expensive repairs and maintains driving safety

- Professional inspection ensures accurate diagnosis and lasting solutions

Identifying the Warning Signs

Drivers often notice subtle changes in their vehicle’s behavior before major issues develop. Paying attention to these signals can prevent minor concerns from becoming expensive repairs. Let’s explore the red flags that suggest your anti-vibration components need inspection.

Unusual Vibrations and Noises

A smooth ride depends on parts that absorb shakes from your motor. When these components wear out, you’ll feel persistent trembling in the steering wheel, seats, or floorboards – especially during idling or acceleration. This shaking often pairs with knocking sounds under the hood as loose parts collide.

Healthy systems silence most operational noises. Thumping or clunking when shifting gears? That’s your cue to get checked. These sounds mean your motor isn’t staying put like it should.

Rough Start and Shifting Movements

Does your car jerk forward when starting or stopping? Worn components struggle to control the motor’s natural torque. You might also feel abrupt lurches when switching between drive modes.

We’ve seen cases where delayed gear changes occur because the transmission shifts position. If your vehicle rocks excessively during basic maneuvers, it’s time for professional evaluation. Our team at Heaven Automotive uses specialized tools to measure movement and pinpoint failing parts.

Key takeaway: Unmanaged vibrations strain surrounding systems. Addressing symptoms early protects your investment and keeps drives comfortable.

Understanding Engine Mount Problems

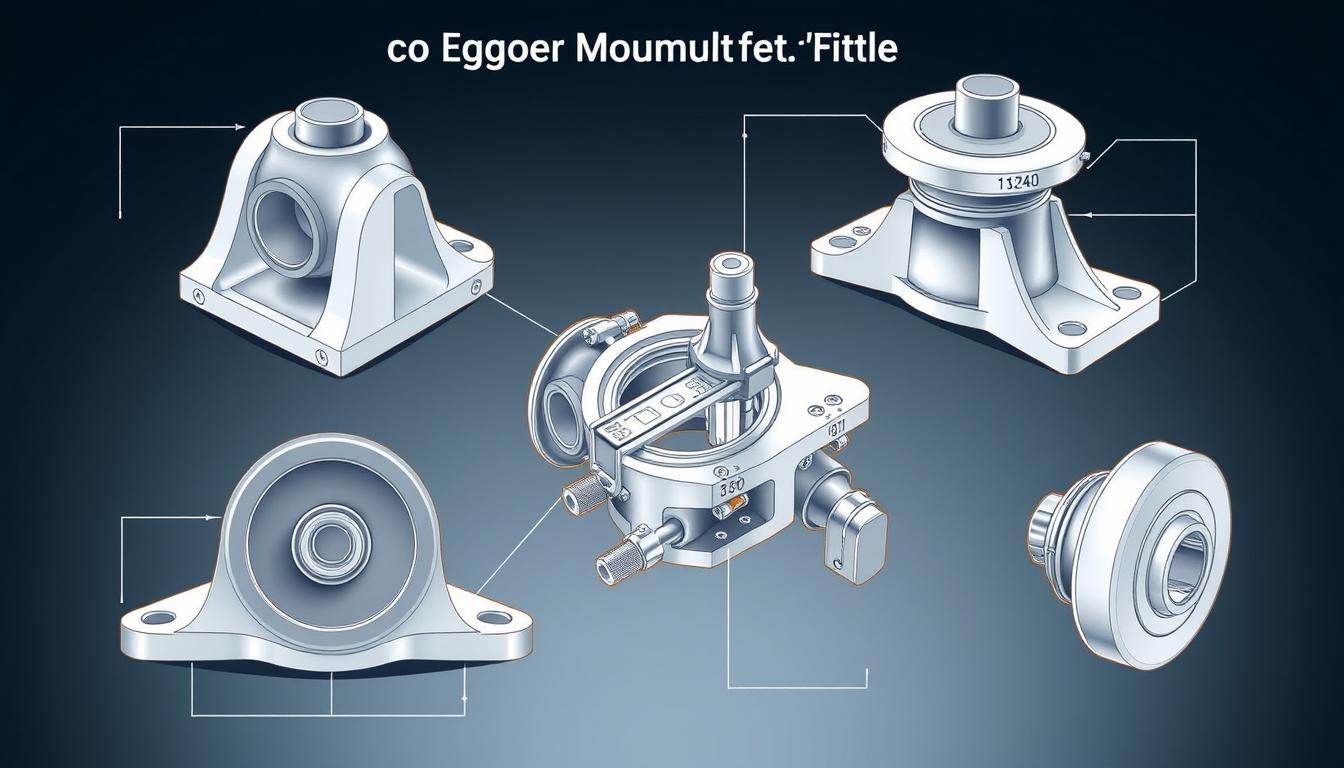

Modern vehicles operate like precision instruments, with every component playing a specific role in performance. The parts connecting your motor to the chassis serve as shock absorbers for the entire drivetrain. Their design balances flexibility with structural support, keeping machinery stable during operation.

The Science Behind Smooth Operation

These critical connectors use layered rubber and metal plates to neutralize shakes. Heavy-duty versions may incorporate polyurethane for extra stiffness in trucks or performance cars. Hydraulic variants add fluid chambers that absorb high-frequency vibrations better than solid materials.

Manufacturers carefully calculate rubber hardness and mount shape to match each vehicle’s needs. This engineering prevents metal parts from grinding against each other during acceleration or bumps. When functioning properly, drivers feel minimal cabin vibration – just smooth power delivery.

When Support Systems Degrade

Cracked rubber or leaking hydraulic fluid destroys a mount’s vibration control. Without proper cushioning, the motor can shift several inches during turns or gear changes. This excess movement strains nearby hoses, wiring, and even transmission linkages.

We’ve observed how worn components create chain reactions. A single failed part in the engine bay often leads to premature wear in adjacent systems. Our technicians use laser alignment tools to detect early-stage issues before they escalate.

Pro tip: Regular inspections catch degradation before it affects drivability. Trust our team at Heaven Automotive to assess your vehicle’s vibration management systems with factory-grade diagnostic equipment.

Common Symptoms and Visual Cues

Spotting early red flags prevents small issues from becoming major headaches. Three key indicators reveal when your vehicle’s vibration control system needs attention – sounds, physical sensations, and visible wear.

Clunking Sounds and Physical Lurching

Metallic bangs during acceleration often signal trouble. These noises happen when your motor shifts excessively, hitting nearby parts. We’ve found worn components typically create three distinct sounds:

- Startup thumps: Brief knocks when turning the ignition

- Gearshift clunks: Loud impacts during acceleration

- Steering rattles: Persistent noise when turning

Sudden jerks when braking or accelerating confirm something’s wrong. Your seat or steering wheel might shake as loose parts struggle to contain movement.

Visible Wear, Cracks, and Fluid Leaks

Open your hood and look where the motor connects to the frame. Healthy mounts show firm rubber with no gaps. Problematic ones display:

- Cracked or flattened cushioning material

- Rusty metal brackets

- Oily residue from hydraulic fluid leaks

Severely damaged parts let the motor sag or tilt. This misalignment strains hoses and wiring in the engine bay. Our technicians at Heaven Automotive use specialized gauges to measure movement precisely.

Don’t ignore these warnings – what starts as minor noise can lead to broken components. Schedule a professional inspection if you spot any symptoms. We’ll diagnose issues accurately and restore your ride’s stability.

Causes Behind Engine Mount Deterioration

Understanding why critical components degrade helps drivers protect their investments. Three primary factors compromise these vibration-absorbing parts – natural aging, physical impacts, and improper maintenance practices.

Time Takes Its Toll

Rubber compounds naturally harden and crack after years of heat cycles and road stress. Even high-quality materials weaken as temperature fluctuations break molecular bonds. We’ve seen original components last 10+ years in mild climates but fail faster in extreme weather.

Collisions and Cutting Corners

Fender benders twist metal brackets, while potholes jar components beyond their design limits. Improper installation creates uneven pressure points that accelerate wear. Leaking fluids pose another threat – oil or coolant softens rubber, reducing its vibration-blocking stiffness.

At Heaven Automotive, our technicians inspect mounts for alignment issues and chemical damage during routine service. We replace worn parts using factory-spec tools, ensuring your motor stays securely positioned. Proactive care prevents cascading repairs – let us help extend your vehicle’s lifespan.